The Joint stock company with foreign investments JSC FI “Uzbekistan factory by storage and processing of scrap, waste of non-ferrous metals " or JSC "UZVTORCVETMET" is the only specialized enterprise in Central Asia for the collection of scrap and waste of non-ferrous metals.

Today the JSC "UZVTORCVETMET" is a modern enterprise that has an extensive network of procurement organizations throughout the country and provides all sectors of the economy with qualitative non-ferrous metals.

This is facilitated by the availability of modern equipment, advanced technology and highly qualified personnel.

Lessons of the past, with confidence to future ...

The motto of the team of JSC "UZVTORCVETMET"

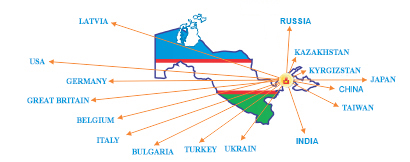

Today the JSC "UZVTORCVETMET" is a modern enterprise that has an extensive network of procurement organizations throughout the country and provides all sectors of the economy with qualitative non-ferrous metals. The management of the plant pays constant attention to the problems of modernization of technical equipment of the enterprise, which significantly affects the quality of products and the expansion of the export potential of the enterprise. Today the products of our company are exported to more than 20 countries. Established partnerships for the supply of products to firms and companies from countries near and far abroad. These are: Scantel LTD Ningbo (China), Sarbak Metall Tig. San.A.S., Kocbay Metall San Vetig LTD Sti, Global Metal San. Ve Dis, Tic.LTD Sti (Turkey), Mednton Inc. (USA), Alex Holding Export-import s.r.o. (Slovenia), Cosma GmbH (Germany), Skantel LTD (Japan), JSC «Рент», «Новослесэк-спорт», JSC «Новые технологии», ООО «Металлком» (RUSSIA), Stenway Invest LTD, Tranzita terminals (Latvia), Ristol Investments Limited (United Kingdom), Malfanta trading LTD, Gloria Trast (Kyrgizstan), TOO SMIT LTD (Kazakhstan), SAGAR OVERSEAS (INDIA), Richfield Industries Inc (Canada). Also recently joined the number of partners: Ai metals (India), Persefona (Chekh Republic), INTAMEX S.A. (Switzerland), AB Metalurunleri savani vedistiret LTD.sti, Birlesikmetal (Turkey), Euromin, MARBELTEKS POROJECTS LLP. (United Kingdom)

The JSC "UZVTORCVETMET" is the holder of the TUV certificate: ISO 9001-2008 and the international BID (Business Initiative Directions), which confirms the quality management system and exemplary comprehensive quality management.

The presence of a clear strategy of the company in market conditions, advanced technologies and cooperation with central and regional authorities provide reliable guarantees for the development of the enterprise in the future.

We are glad to cooperate with all interested enterprises and trade organizations.

Our enterprise is located in the industrially developed and deservedly named "Star of the East" in the city of Tashkent. Detailed contact information can be found in the relevant section of our website..

THE MAIN ACTIVITIES OF THE ENTERPRISE

Collection and processing of non-ferrous scrap:

- Collection of scrap and non-ferrous metal waste;

- Primary processing (sorting, cutting, cutting) and processing of non-ferrous metals scrap;

- Collection and processing of used and old lead-acid batteries.

Production:

- Different grades of aluminum alloys;

- Copper based alloys (bronze and brass);

- Alloys of zinc and lead;

- Products from aluminum alloys;

- Articles made of bronze and brass alloys;

- Production and sale of housewares accessories from aluminum;

- Cooperated production and sale of copper rod and copper cathodes, batteries.

Provision of services:

- Determination of the chemical composition of non-ferrous alloys;

- Manufacturing of castings of various sizes from alloys of non-ferrous metals;

- Machining of castings from non-ferrous alloys;

- Development of technical conditions and standards for products from non-ferrous metals, with their registration in the Agency "Uzstandart".

JSC FI "UZVTORCVETMET" – is an enterprise with more than 75-year history. Many significant events of the political and economic life of the Republic of Uzbekistan, the main stages of the development of the metallurgical industry, were reflected In the chronicles of the plant.

1939-1973

In 1939 the "Tashkent Inter-Republican Office for the Preparation, Processing and marketing of Secondary Non-Ferrous Metals" was formed. Its activity consisted in supplying the enterprises of the metallurgical industry with secondary non-ferrous metals. After the Second World War, with the development of industry, the demand for ferrous and non-ferrous metals began to rise. In 1948 the enterprise was reorganized into the General Directorate for the procurement, processing and marketing of secondary metals (Glavvtormet). As a result, there was a significant growth in the processing of non-ferrous metals, raw materials were supplied from all countries of Central Asia. Other directions of activity began to develop in the enterprise. In particular, a special factory laboratory was organized, processing of up to 2 tons of ferrous and non-ferrous metals per year was established.

In 1966 the structure of the plant changed, the production and procurement management of Vtorsvetmet was formed, the tasks of which were the collection and processing of ferrous metals. Despite the expansion of activities and the constant demand for manufactured products, in fact, "Vtorsvetmet" remained in the status of the base.

1973-1991

In 1973 in the base of "Vtorsvetmet", the Tashkent Aluminum Alloy Plant was built - a large-capacity mechanized production complex for the pyrometallurgical processing of scrap and non-ferrous metal waste and the production of aluminum alloys (secondary aluminum). With the establishment of the plant due to the demand for products from the Central Asian republics of the former Soviet Union, the foundation of today's enterprise, the JSC UZVTORCVETMET", was created. In September 1973, a double-chamber reverbatory furnace was installed in the 1st workshop of the plant. A year later, starting from 1974, the plant began to manufacture secondary aluminum and operate with a capacity of 52,000 tons of products per year. In 1975-1976 in the second smelting plant two more two-chamber furnaces were installed. In 1976-1977 in the third workshop, lines for drying chippings were installed. In 1980-1982, the induction furnace brand "IAT-6M2" was installed in the 2nd smelting plant. Over time, the production capacity of the plant has increased dramatically, and in 1985-1988, the plant's production figures were 55 tons of products per year. This became possible due to the supply of raw materials not only from the Central Asian republics, but also from the Kemerovo region of the Russian Federation. The delivery of products from these countries was carried out on the basis of contracts concluded at the beginning of each year. The work of the plant was organized in three shifts.

1991-2000

Before independence of the Republic of Uzbekistan, the plant had been working for some time on the processing of ferrous metals, and the plant itself was merged with “Uzmetkombinat”. The plant got its second life thanks to the state strategy of Uzbekistan as a country that chose an independent development path in 1991. In accordance with the Resolution of the Cabinet of Ministers of the Republic of Uzbekistan No. 160 dated March 24, 1994, the production association "Vtortsvetmet" was transformed into an open joint-stock company "Uzvtorcvetmet". The regional bases for the collection of non-ferrous metals were created in each region of the republic. They were equipped with the necessary machines and tractors. Due to a significant flow of investments, the Uzbek-Indian joint venture “Handicraft”, specializing in the production of consumer goods on the basis of the enterprise. In addition, the production of pistons for the company called “Novator” was organized. Also, small companies like “METAL” began to operate in the plant. During this period, the plant was reconstructed and modernized and new equipment was installed. It should also be noted, that with the accelerated development of the industrial sector, the demand for ferrous and non-ferrous metals has increased. Therefore, the issues of prevention of theft of production and technical equipment, scrap and non-ferrous metal waste, protection of the economic interests of the republic, as well as rational use of valuable raw materials have acquired particular urgent importance. In accordance with the Decree of the President of the Republic of Uzbekistan No. PD-2212 of February 5, 1999 "On the regulation of exports of scrap and non-ferrous metals waste", Decree of the Cabinet of Ministers of the Republic of Uzbekistan No. 49 "On the procedure for storing, keeping and delivering scrap, waste of ferrous and non- ferrous Metals "and the Decree of the President of the Republic of Uzbekistan of 4 March 2000" On measures to prevent theft and illegal export of scrap and non-ferrous metals waste" was banned for the export of scrap and non-ferrous metals waste outside the republic.

2000-2006

Since 2000 company has begun the modernization of production lines. Special attention was paid to the further development of international relations. As a result, the plant was awarded a grant from the World Bank, and then the government of Japan. This allowed to modernize the production technologies of the plant, the newest equipment was installed. The laboratory of the plant was equipped with the equipment of the German brand "Spectrolab", which fully meets domestic and international standards. With the increase in demand for products, the requirements to the quality of manufactured products have also increased, and its range has expanded. Undoubtedly, metal processing is an efficient spector of the economy. It is especially important to process the domestic scrap of metals and produce high-quality export-oriented products. Proceeding from this, the plant's staff began to pay special attention to increasing the volumes of collection and processing of unsuitable metals, as well as work on tolling bases. This allowed the company not only save significant funds, but also to develop faster. So, since 2002, production capacities have increased, and the annual production of other non-ferrous metals has amounted to more than 2 thousand tons.

2006-Present time...

In 2006, the reorganization of JSC "Uzvtortsvetmet" and its regional divisions was carried out, and on their basis JSC FI “Tashkent factory by storage and processing of scrap, waste of non-ferrous metals was organized. The statutory fund of JSC "UZVTORCVETMET" was approved in the amount of more than 2.2 billion soums with a share held by the state in the amount of 50.5 percent. Reforming, modernization, introduction of energy saving and environmentally friendly technologies at the enterprise has become a key strategic task. In February 2007, the national standard UzDST ISO 9001-2000 and in June 2012 - UzDST ISO 9001-2009 was introduced. High results were given by the implementation of ISO 14001 environmental management standards and OHSAS 18001 industrial safety management. In September 2012, the management of international quality was introduced at the plant in order to move to the requirements of the ISO 9001: 2008 standard. Today's achievements are rightly proud of the plant, and JSC "UZVTORCVETMET" is positioned as the number one company for the procurement and processing of non-ferrous metals scrap in the Central Asian region. The high-quality products manufactured by the plant are able to compete with the products of leading foreign manufacturers. Over the years of market reforms, the joint-stock company has achieved a leading position in the field of recycling of non-ferrous metallurgical raw materials, and does not stop with these achievements.

Human resources are the basic value and one of primary factors of successful development of the enterprise. JSC FI "UZVTORCVETMET" aspires to create the conditions promoting increase of efficiency of activity and an involvement of the personnel in realization of corporate tasks, and providing transparency and an openness of approaches and principles in sphere of human-resource management.

Social policy of the enterprise is formed and realized on a system basis according to the authorized normative documents. For achievement current and long-term objectives of development in joint-stock company, programs on work with human-resources are developed and realized.

Purposes of a policy of safety and labor safety are:

- Creation of healthy and safe working conditions due to the achievement of a level of productions corresponding to a modern condition of technical equipment’s and achievements of a science, being guided by a principle priority lives and health of workers in relation to results of industrial activity;

- Formation at workers of the enterprise of the steady motivational mechanism of safe behavior on manufacturing, development of skills of people to anticipate and warn occurrence of extreme situations on manufacturing.

For this purpose the enterprise solves the following tasks:

- Raises a level of industrial safety of industrial objects due to maintenance of reliability, safe and trouble-free operation of the process equipment;

- Provides decrease of risks, including the dangerous and harmful production factors connected to an opportunity of drawing of damage of a life and health of workers;

- Improves a control system of a labor safety and industrial safety on the basis of best world standards considering global experience, adapted to specificity and industrial conditions of a factory;

- Raises efficiency of industrial control compliance with labor protection and industrial safety requirements;

- Develops and stimulates the personal and collective responsibility of employees for compliance with labor protection and industrial safety requirements;

- Propagates and implements the widest possible application of best practices, local and foreign, on the formation of a motivated mechanism for safe workplace behavior, responsibility for their lives and health, and for the life and health of those working next to it.

| Resellers in the bazaar |

|

| Reception point Uzvtorcvetmet |

|

| I throw in the trash |

|

UZ

UZ RU

RU EN

EN